-

Read more ...

Print businesses are making it a high priority to diversify their large format print offering as customers increasingly demand unique ideas, more creative solutions, and new content. However, business leaders are aware something needs to be done, but many don't know where to start.

The solution is to begin the journey of transformation so they can offer more competitive services that will shape the future. Not only will it help businesses serve existing customers better, but it will also enable them to enter new markets, innovate new print solutions, find fresh revenue opportunities, and scale up their offerings into the future.

Transformation is definitely on the minds of many print businesses. Two-fifths regard diversification of their large format print offering as a high priority, according to a survey from Widthwise in 2020. This could come from providing new products and services to existing customers or finding innovative ways to build an additional customer base. There are many ways to evolve.

Why is now the time to transform

Demand for wide format printers is expected to rise over the next few years. One estimate from Report Linker valued the global market at $3.4 billion in 2020, projecting it to reach $4 billion by 2027.

This, of course, follows the economic effect of the pandemic which depressed demand and revenues for many print businesses as offline retail opportunities were scaled down, conferences and events were canceled, and travel was limited. In fact, revenue for the printing services industry declined an estimated 12.2% in 2020 as businesses cut

back on advertising and marketing expenditures.However, the print world is an ever-changing one, and print businesses must stay sharp. The way to secure new business

in the years ahead is to innovate and pivot your offerings to meet market demand, while also delivering reliable and efficient services.Innovating in new areas could benefit your business

The future holds many opportunities for PSPs to innovate, interior decor being a great example. This covers many things, from fine art to durable upholstery, but the size of the opportunity is massive. Just consider that the global digitally printed wallpaper market has been predicted to grow at 23.6% annually (CAGR) until 2025, to reach a total value of $10.4 billion, according to figures from Energias Market Research.

Printed packaging and labels are another growth area, driven by the increasing use of printed corrugated material in retail-ready packaging as well as in e-commerce, according to market report publisher Smithers. The consultancy estimates that the total value for printed packaging and labels reached $431.6 billion in 2020 and will continue to expand at a CAGR of 2.6% to reach $491.1 billion in 2025.

How content requirements are expanding the possibilities

In addition, print businesses are dealing with customers who have unprecedented demands and expectations around content. They have witnessed the meteoric rise of web-based content creation platforms such as Canva and Zazzle. These enable consumers to remotely design and print professional posters and brochures and a full range of merchandise, using predefined and customizable graphics and designs.

What’s more, consumers have become accustomed to buying goods and services from easy-to-use e-commerce platforms that offer next-day, or even same-day, delivery. While providing stiff competition, it also opens up the possibilities for print businesses to expand their service portfolios through online and e-commerce.

Online platforms’ broad reach also enables businesses to explore new geographies and customer demographics. And if you don’t have the resources to expand your own digital content services, you could partner with an existing online provider to enter new web and mobile markets.

-

Read more ...

FlexCut is an included feature that is available on all Summa vinyl plotters, the S One Series and the S Class 2 Series. This functionality is developed to add more flexibility to your production flow. Keep your cut material together with FlexCut while you can cut through simple designs in the media, without damaging your roll plotter.

How it works

By alternating between cutting through the media and half cutting the vinyl, the Summa vinyl plotter creates small media "bridges". These bridges allow the cut media to stay together.

With these small bridges and the intelligence behind a Summa vinyl plotter, you can cut a whole row or roll of designs. What's more:

- The designs can be taken out with the ease

- Perform FlexCut in one simple step (press start and let your summa vinyl cutter will do the rest)

- Cut through the material without damaging your roll plotter

And if these benefits were not enough, as an added bonus, the FlexCut vinyl roll can easily be transported because the cut designs remain together while the media's rigidity is maintained.

Use FlexCut on your Summa today!

You can use FlexCut today by following these straightforward actions:

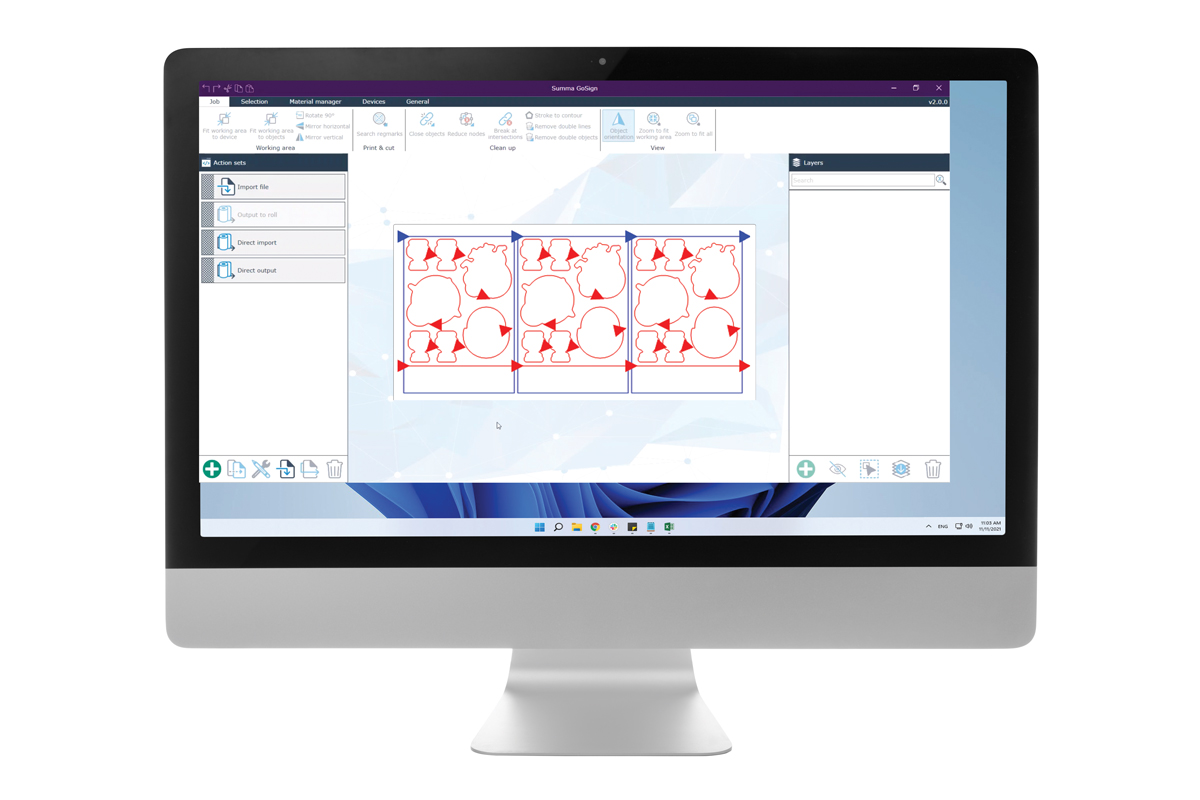

Prepare your cut file by indicating what needs to be a FlexCut, you can do this by using blue lines, the red lines will be regular cuts.

This method enables the GoSign software to detect the difference between the data that needs to be FlexCut and the data that needs to be a regular cut. GoSign software is Summa's own cutting software tailored to the range of Summa's vinyl cutters. The software is included with every Summa S One and S Class 2 series.

The software will end the data that needs to be contour cut first. Then, it will activate FlexCut in order to alternate between cutting through and partially cutting through. While doing so, it will create an easy tear-off line.

It is worth trying out this feature with your cutter!

-

Read more ...

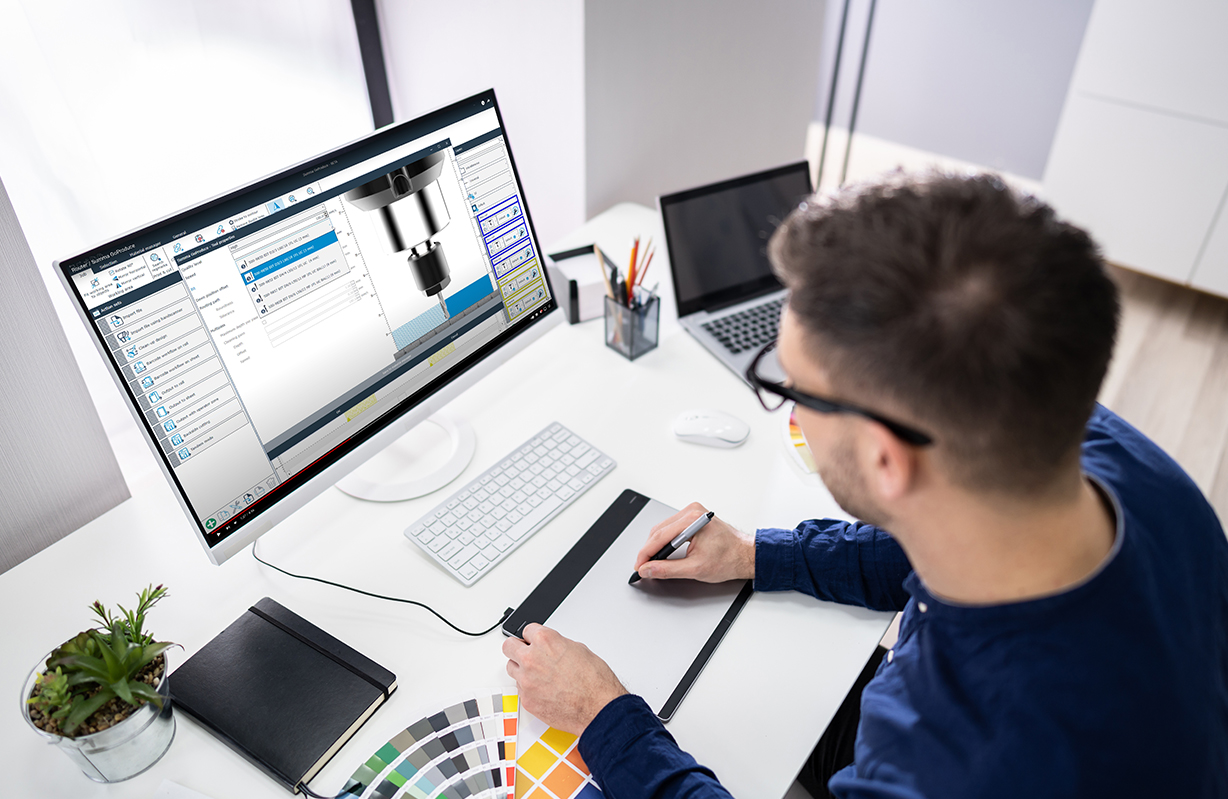

Every single one of you, working with printed or non-printed materials to cut and finish, know how vitally important software is to the usability and productivity of your hardware. This is not just a matter of integrating your print and cut workflow. Also, the presence of an intuitive interface, easy navigation, and intelligent features help the operator handle jobs more efficiently.

Summa recognizes the importance of software that is fully tailored to the hardware. To underline the importance, Summa developed its very own software platform entirely in-house: GoSuite. GoProduce for the F Series has been the first software module within GoSuite, which is designed to optimise the F Series users' workflow.

Smart functionalities at your service

Adding to the intuitive interface and modern look, one of the true strengths of GoProduce are the straightforward action sets, enabling the operator to handle variable jobs in a natural, trouble-free and automated way. There are various default action sets in GoProduce to support your Summa workflow, such as the barcode automation, ready to be used at a click of a button. To further enhance flexibility, you can adjust many of these action sets to your hand and your needs.

Discover the Material Database

The material database is a vital key to the user-friendliness of the GoProduce software. It includes an extensive range of material types, the materials contain the cutting settings and tool data defined by Summa. These materials can be adapted to your specific needs at all times.

The database ensures a smart collaboration between jobs, materials, and on-site tools. The material manager works with pre-defined methods, meaning that you only need to choose the material you want to process and the material manager itself automatically chooses the correct tool and its settings to process it with.

Supporting Back Side Cutting with edge detection

Back side cutting is especially useful when cutting cardboard boxes in order not to damage the print and in order to ensure the print is located on the outside of the box. GoProduce includes a specific camera profile enabling you to perform backside cutting with smart edge detection;

Basically, there are two methods of back side cutting within GoProduce:

- Original: in this method, the camera will first read the marks in the artwork. The marks will then be cut out in squares. After that, you need to flip the sheet, the camera starts reading these cutout marks again and the flatbed cutter starts to cut.

- With edge detection: this method is available since the 1.10 version of GoProduce. The camera will read the marks in the artwork first and then it will read 3 edges of the sheet. Thereafter, you flip the sheet and the flatbed cutter will read two edges again to determine the position of the artwork. The machine starts to cut without the need to cut out the markers first. This will save you a considerable amount of time.

Automated Workflow with Barcode functionality (Pro Pack)

The flatbed cutters usually need an operator to select the right cutting file, then read the printed marks to register the correct position of the material and match the selected cutting file. With the barcode functionality, the cutter reads the printed barcode, identifies the job, and automatically retrieves the cutting file. In this file, all the necessary cutting data and tool selection can be stored thanks to GoProduce. The built-in camera of the flatbed scans the job automatically (or alternatively by hand scanner). See how it works in the video below:

Continuous development of new features and improvements

The GoSuite software range is growing and Summa continues to develop new features and improvements. The GoSuite software platform is built to support you today and in the future, with many more software solutions to follow. With GoProduce for the Summa F Series, you can benefit from all the latest features and techniques on your F Series cutter. Did you know that you can easily upgrade your SummaFlex software to GoProduce?

Skip to Content

- Create an Account

- Offers for you

+44 (0) 1527 853 136